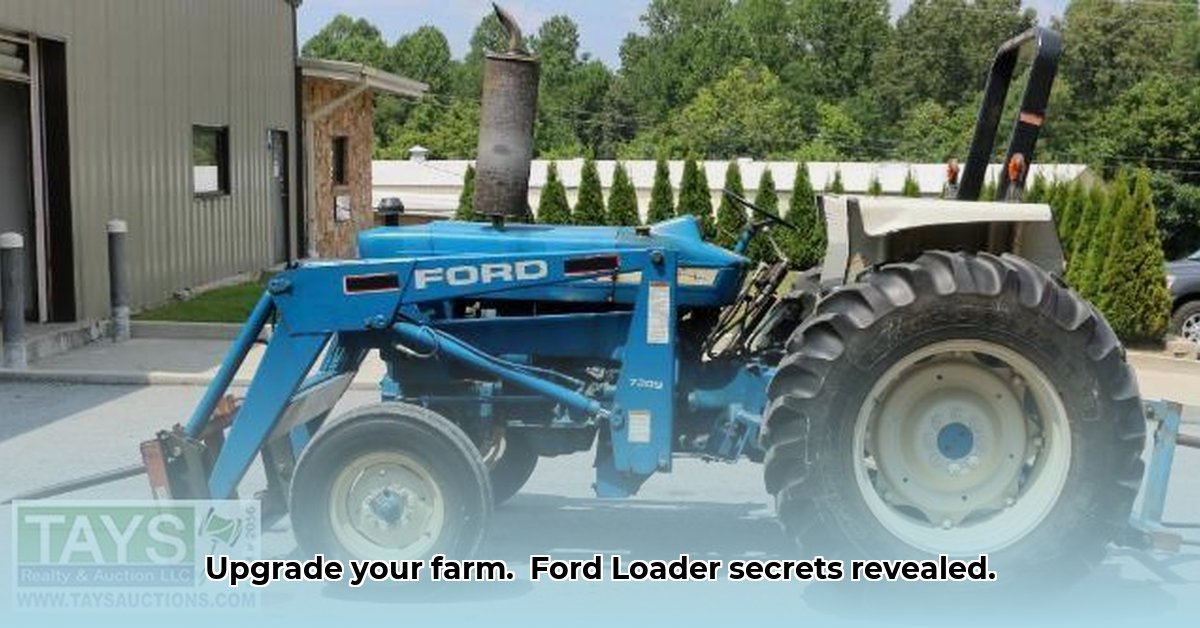

Ford tractors—icons of agricultural history—continue to play a role in modern farming. This guide explores the sustainable use of older Ford tractors, specifically focusing on their front-end loaders, offering practical advice for maintaining, upgrading, and integrating them into environmentally responsible farming practices. Whether your Ford tractor is a recent acquisition or a well-loved family heirloom, this guide provides actionable steps to maximize its efficiency and longevity. We'll balance the advantages of using older equipment with the need for sustainable practices for a more environmentally responsible future. For more information on finding suitable front-end loaders, check out this resource.

The Sustainability of Vintage Ford Tractors: A Balanced Perspective

The use of older Ford tractors, particularly those equipped with front-end loaders, presents a unique sustainability challenge. While manufacturing new equipment consumes significant resources and energy, restoring and maintaining existing machinery reduces this environmental footprint. However, older engines typically consume more fuel and produce higher emissions than their modern counterparts, impacting overall sustainability. The optimal approach—repairing and utilizing existing equipment versus acquiring new machinery—depends on a careful cost-benefit analysis, factoring in your farm's specific needs and priorities. This decision requires a balanced view, weighing initial investment versus long-term operational costs and environmental impact. What are your priorities: minimal upfront costs or maximum long-term sustainability?

Giving Your Old Ford New Life: Practical Maintenance and Upgrades

Maintaining your older Ford tractor and front-end loader is crucial for maximizing its lifespan and minimizing environmental impact. Regular maintenance reduces breakdowns and extends the machine's useful life, thereby reducing the need for frequent replacements. Sourcing parts for older equipment may require more effort, often involving specialized dealers, online marketplaces, or resourceful repair techniques. Let's outline a practical strategy.

Establish a Rigorous Maintenance Schedule: Implement a proactive maintenance plan. Regular oil changes, hydraulic system checks, and diligent monitoring of wear and tear prevent costly breakdowns. Schedule maintenance at consistent intervals – preventative care is far more cost-effective than emergency repairs.

Develop a Proactive Parts Sourcing Strategy: Locate reliable sources for parts before you need them. Establish relationships with local mechanics specializing in older Ford tractors; their expertise is invaluable. Cultivate a network of suppliers to ensure consistent access to necessary components.

Engine Optimization for Fuel Efficiency: Consider upgrading your engine to enhance fuel efficiency. While requiring investment, long-term fuel savings can significantly outweigh the initial cost. Professional engine tuning can optimize fuel injection and combustion, often dramatically reducing fuel consumption.

Explore Sustainable Fuel Alternatives: Investigate the use of biodiesel or other environmentally friendly fuels to minimize emissions and reduce reliance on fossil fuels. Biodiesel, derived from renewable sources, offers a significantly lower carbon footprint compared to traditional diesel.

Integrate Modern Technology: Retrofit older tractors with modern precision agriculture technologies. While seemingly a substantial undertaking, this can significantly enhance efficiency, reduce waste, and improve overall farm sustainability. GPS-guided systems for planting, fertilization, and spraying can dramatically improve yields while reducing resource consumption.

The Long-Term Vision: Sustainable Farming for Generations to Come

While maintaining older equipment is a valid strategy, transitioning to more fuel-efficient, modern machinery should be considered as part of a long-term sustainable farming plan. A gradual equipment replacement strategy, phasing out older models and integrating newer, sustainably designed tractors, provides a balanced approach. This phased transition allows for cost-effective upgrades over time while still reducing environmental impact.

A Comparative Analysis: Older Ford vs. New Technology

The decision between retaining your trusty older Ford tractor and purchasing new technology requires careful consideration. Let's weigh the advantages and disadvantages:

| Feature | Advantages | Disadvantages |

|---|---|---|

| Initial Cost | Significantly lower than purchasing new equipment. | |

| Parts Availability | Can be challenging to source; older parts may be expensive or scarce. | Requires extensive searching and potentially higher costs for specialized parts. |

| Fuel Efficiency | Generally lower fuel efficiency than modern tractors. | Higher operating costs due to increased fuel consumption. |

| Environmental Impact | Higher emissions compared to newer, more efficient models. | Greater contribution to greenhouse gas emissions. |

| Technological Integration | Integrating modern technology can be difficult and expensive. | Limitations in implementing precision farming techniques. |

| Durability | Ford tractors are renowned for their robust construction and durability. | Even durable machines require significant repairs, which can be costly. |

This table highlights that while older Ford tractors offer cost advantages, their environmental impact and technological limitations should be carefully evaluated. The ideal approach depends on your farm's specific needs, budget, and long-term sustainability goals.

Retrofitting Older Ford Tractors for Sustainable Practices: A Step-by-Step Guide

Key Takeaways:

- Older Ford tractors offer advantages in durability and simpler repair, resulting in lower maintenance costs and reduced environmental impact from manufacturing.

- Sustainability involves fuel choice (e.g., biodiesel), adopting eco-friendly farming technologies, and community engagement.

- While initial restoration costs can be high, longer-term environmental and economic benefits often outweigh this investment. A thorough cost-benefit analysis is essential.

- Community resources and collaborative knowledge sharing are crucial for sourcing parts and expertise.

Step 1: Thorough Tractor Assessment

Before any retrofitting, thoroughly evaluate the tractor's condition. Assess its structural integrity, current fuel consumption rates, and the overall mechanical soundness. This assessment guides your restoration plan, informing the prioritization of necessary repairs and upgrades. A comprehensive evaluation helps determine the feasibility and ultimate cost of the retrofitting process.

Step 2: Prioritizing Fuel Efficiency Upgrades

Improving fuel efficiency is crucial for minimizing environmental impact.

Biodiesel Conversion: Consider converting your tractor to utilize biodiesel, reducing reliance on fossil fuels. This significant upgrade requires professional guidance and careful planning to ensure compatibility and safe operation.

Engine Tuning: Professional engine tuning can significantly boost fuel efficiency. Tuning optimizes the fuel injection and combustion processes, minimizing fuel consumption without necessitating major component replacements.

Maintenance for Maximum Efficiency: Regular oil changes, filter replacements, and proper tire inflation significantly improve fuel economy. These are simple yet vital steps in maximizing the efficiency of your older tractor.

Step 3: Integrating Sustainable Farming Technologies

Modern technology can enhance sustainability:

Precision Farming Technologies: Integrate GPS-guided systems for precise planting, fertilization, and spraying, minimizing resource waste and maximizing yields.

Low-Impact Tillage Implement Upgrades: Utilize implements designed for conservation tillage to reduce soil disturbance. Appropriate implements help minimize soil erosion and protect soil health.

Enhanced Front-End Loader Performance: Upgrading the front-end loader improves operational efficiency, providing optimal weight distribution for various tasks and reducing fuel consumption through optimized handling.

Step 4: Financial Planning and Community Collaboration

Retrofitting requires careful financial planning. Thoroughly assess the costs associated with parts, labor, and potential modifications. However, remember this investment contributes to long-term environmental stewardship and potentially increased economic returns. Leveraging community resources, such as forums and experienced mechanics, provides valuable assistance and knowledge sharing.

Classic Tractor News